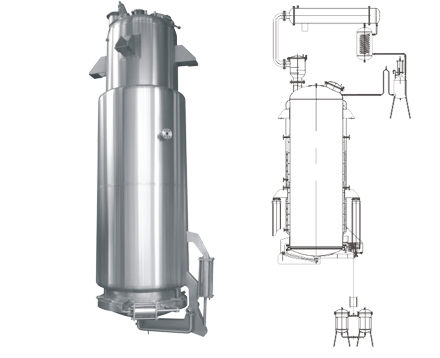

TQ-Z(DTH) VERTICAL WIMBLE TYPE EXACTING TANKS

Equipment characteristics

The equipmen be applied to the multiple technology operation of normal pressure, micro pressure, water frying, warm soaking, thermal reflux, compulsory circulation, filtration, redolent oil extraction and organically solvent recycling in traditional Chinese medicine, food and chemical industry. The prominent characteristics of the large and small taper type extracting tank is that the slagging is very convenient with good heating effect.The tank body is equipped with CIP cleaning automatic rotary spraying ball head, temperature measuring hole, explosion-proof view lamp, view mirror, rapid open feeding inlet etc., which can guarantee the convenient operation and is in accordance with GMP standard. The tank body inside the equipment is made of imported SUS304, and the jacket is made of completely sealed aluminum silicate blanket for temperature holding. The external tank body is stuck with SUS304 semiluster thin steel sheet for surface decoration. The complete equipment supplied shall include: Defoamer, condenser, cooler, oil and water separator, filter and control desk for cylinder etc. Accessories.

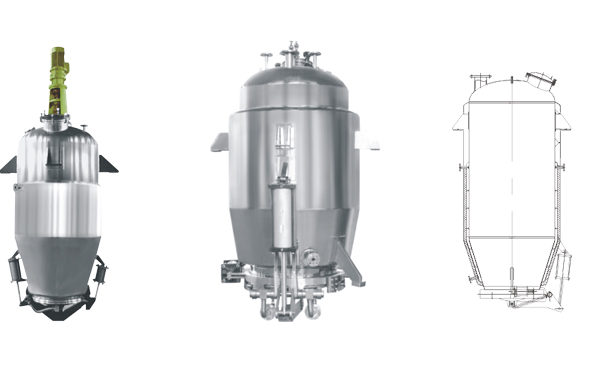

TQ-A(DTH) VERTICAL WIMBLE TYPE XACTING TANKS

Equipment characteristics

The equipment is applicable for the multiple technology operation of normal pressure, micro pressure, water frying, warm soaking, thermal reflux, compulsory circulation, filtration, redolent oil extraction and organically solvent recycling in traditional Chinese medicine, food and chemical industry. The tank body is equipped with CIP cleaning automatic rotary spraying ball head, temperature measuring hole, explosion-proof view lamp, view mirror, rapid open feeding inlet etc., which can guarantee the convenient operation and is in accordance with GMP standard. The tank body inside the equipment is made of imported SUS304, and the jacket is made of completely sealed aluminum silicate blanket for temperature holding. The external tank body is stuck with SUS304 semi-luster thin steel sheet for surface decoration. The complete equipment supplied shall include: Defoamer, condenser, cooler, oil and water separator, filter and control desk for cylinder etc. Accessories.

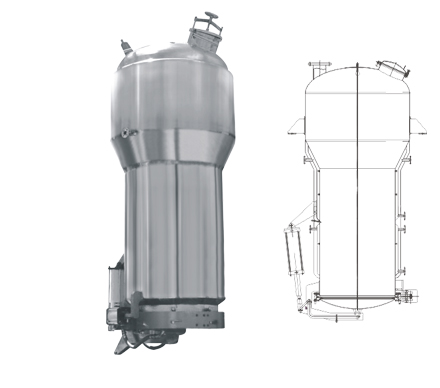

TQ-M(DTH) MUSHROOM TYPE EXACTING TANKS

Equipment characteristics

The equipment is applicable for the multiple technology operation of normal pressure, micro pressure, water frying, warm soaking, thermal reflux, compulsory circulation, filtration, redolent oil extraction and organically solvent recycling in traditional Chinese medicine, food and chemical industry. The prominent characteristics of the large and small taper type extracting tank is that the slagging is very convenient with good heating effect.The tank body is equipped with CIP cleaning automatic rotary spraying ball head, temperature measuring hole, explosion-proof view lamp, view mirror, rapid open feeding inlet etc., which can guarantee the convenient operation and is in accordance with GMP standard.

The tank body inside the equipment is made of imported SUS304, and the jacket is made of completely sealed aluminum silicate blanket for temperature holding. The external tank body is stuck with SUS304 semi-luster thin steel sheet for surface decoration. The complete equipment supplied shall include: Defoamer, condenser, cooler, oil and water separator, filter and control desk for cylinder etc. Accessories.

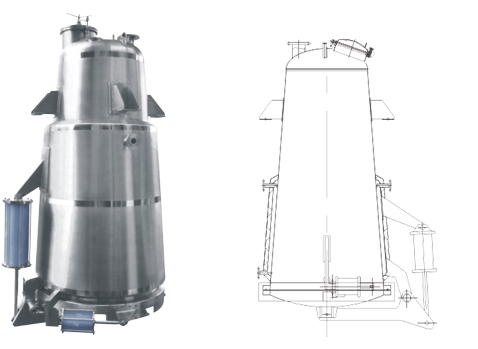

TQ-B(DTH) LARGE AND SMALL TAPER TYPE EXTRACTING TANK

Equipment characteristics

The equipment is applicable for the multiple technology operation of normal pressure, micro pressure, water frying, warm soaking, thermal reflux, compulsory circulation, filtration, redolent oil extraction and organically solvent recycling in traditional Chinese medicine, food and chemical industry. The prominent characteristics of the large and small taper type extracting tank is that the slagging is very convenient with good heating effect.The tank body is equipped with CIP cleaning automatic rotary spraying ball head, temperature measuring hole, explosion-proof view lamp, view mirror, rapid open feeding inlet etc., which can guarantee the convenient operation and is in accordance with GMP standard.

The tank body inside the equipment is made of imported SUS304, and the jacket is made of completely sealed aluminum silicate blanket for temperature holding. The external tank body is stuck with SUS304 semiluster thin steel sheet for surface decoration. The complete equipment supplied shall include: Defoamer, condenser, cooler, oil and water separator, filter and control desk for cylinder etc. Accessories.

Rotary type residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can be realized, and more than 3Bar can be achieved in the swivel type product. It provides more selection for extracting technology. It can also meet some special technological requirements. With good safety and reliability, it has sufficient safety guarantee functions and the has no leakage.

Rapid open safety discharging door

The tank cover can be automatically opened and closed. It adopts cylinder control and is provided with safety device to avoid accidental operation and provide high safety factor. It is suitable for use in small and medium-sized reside discharging vent.

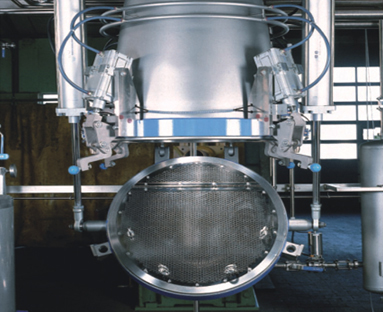

Large-diameter residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can be realized to provide more selection for extracting technology. With high safety factor, the residue discharging door is suitable for residue discharging of large-diameter upside-down taper type extracting tank.

Technology parameter

| Apecifications | TQ-0.5 | TQ-1 | TQ-2 | TQ-3 | TQ-4 | TQ-6 | TQ-8 | TQ-10 |

| Volume(L) | 600 | 1200 | 2300 | 3200 | 4300 | 6300 | 8500 | 11000 |

| Design pressure inside tank(Mpa) | 0.09 | |||||||

| Interlayer design pressure(Mpa) | 0.3 | |||||||

| Diameter of feeding mouth(mm) | 400 | 400 | 400 | 400 | 500 | 500 | 500 | 500 |

| Heating area(m2) | 2.4 | 3 | 4.7 | 6.8 | 8 | 10 | 12 | 12 |

| Condensate area(m2) | 3 | 4 | 5.4 | 8 | 10 | 10 | 15 | 18 |

| Area of cooling surface(m2) | 1 | 1 | 1 | 1 | 1 | 2.2 | 2.2 | 3 |

| Filter area(m²) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.3 | 0.3 | 0.3 |

| Dregs gate diameter (mm) | 600 | 800 | 1000 | 1200 | 1200 | 1400 | 1500 | 1600 |

| Steam consumption(kg/h) | 285 | 285 | 346 | 570 | 660 | 718 | 903 | 1140 |

| Consume water(T/h) | 2.1 | 2.1 | 2.5 | 4.2 | 4.5 | 5.5 | 6.7 | 6.7 |

| Heating pipe mouth (mm) | 32 | 32 | 32 | 40 | 40 | 50 | 50 | 50 |

| Exhaust pipe (mm) | 100 | 100 | 100 | 125 | 125 | 150 | 150 | 150 |

| Cooling water pipe (mm) | 40 | 40 | 40 | 50 | 50 | 50 | 65 | 70 |

| Motor power(KW) | 2.2 | 2.2 | 3 | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

| Agitation speed(f/min) | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 |